TSL 0601G : Automotive accelerated weathering standards

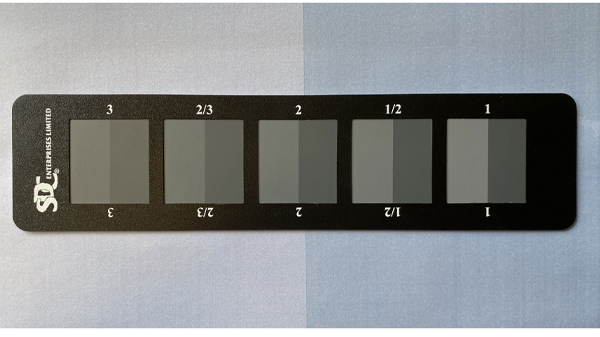

TSL 0601G Toyota – Change in colour by ageing.

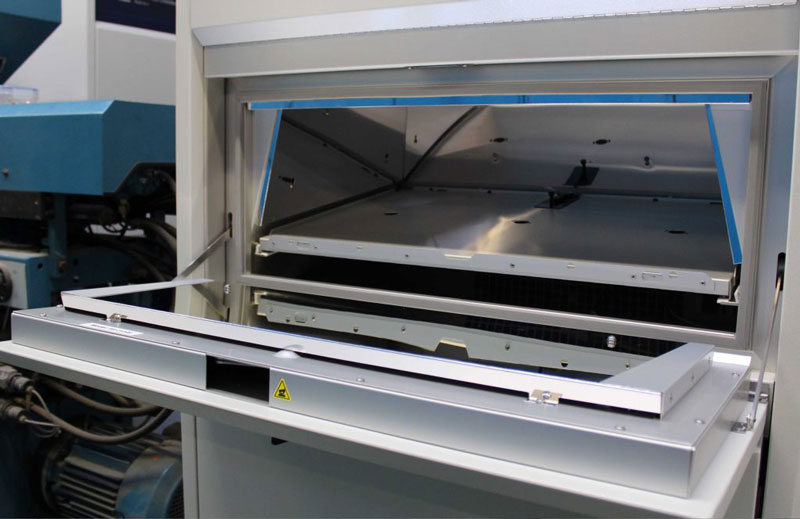

Xenon lamp ageing test integrates optical radiation, temperature, relative humidity, moisture and other ageing factors. It simulates the climate environment under the circumstance of using indoor and outdoor light sources, all within a xenon arc test chamber. At the same time, it combines temperature and humidity with water spraying period. TSL 0601G test standard is used by most automotive companies to carry out artificial accelerated weathering and light ageing testing.