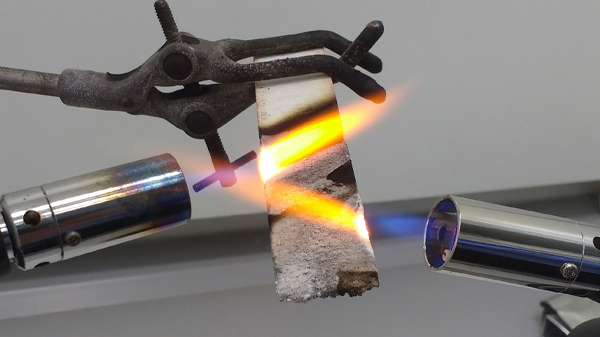

Our Fire Testing Services

Our lab has the capabilities to carry out small scale fire testing in order to help you understand the flammability of your material or product. We can test to UL94, ASTM, and ISO standards, which are listed below. We can perform flammability within industries such as automotive, consumer goods and electrical. However, our expert team are able to advise on bespoke setups to replicate the real world application and performance of your product.