Lithium Battery Testing – Thermal Runaway

Bespoke arrangements for a European Commission established Project

To understand the thermal runaway behaviour of lithium metal or Li-ion batteries, we often have to induce thermal abuse to the battery or cell itself. Impact Solutions has a battery testing chamber which is built in accordance to the guidelines in SAE AS 6413, a drafted standard, which allows Impact to induce thermal abuse to Li-ion batteries in a controlled environment. Upon our research, Impact has identified some key factors that will affect the thermal behaviour of a cell including,

- Position of heater source

- Contact area between heater cartridge and cell

- Ramp rate of heater source

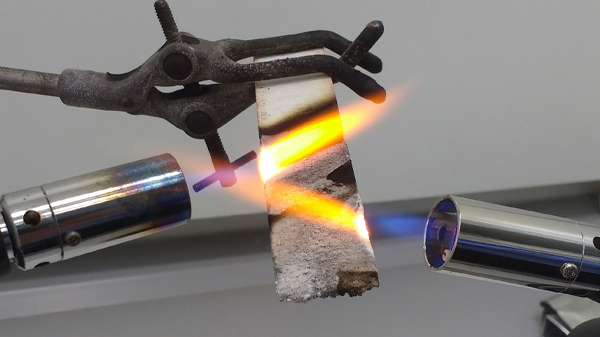

For these reasons, Impact has designed a bespoke heater cartridge that will maximise the contact area between the cell and the heater in a localised region. This will allow us to induce thermal abuse leading the cell to enter thermal runaway as required and enable us to achieve consistent results. This bespoke heater cartridge is suitable for a range of different cells including 18650 Li-ion cell and 21700 cells. Alongside the capability of live monitoring the temperature changes throughout the process, it enables our team to predict the type of thermal event.

This bespoke set-up allows the Project Sabatair team to monitor, record and analyse the thermal behaviour of batteries by accurately collecting the key data for research. These data will directly impact the future of lithium-metal or lithium-ion batteries being transported as cargo in passenger aircraft. One of the project objectives is to evaluate the effectiveness of potential mitigating measures against fire risks of lithium-based batteries. A key mitigating measure that was heavily researched is the different types of packaging options which may reduce or eliminate the propagation of heat from a failed cell. Impact solutions set-up the different packaging methods outlined by the SAE AS 6413 in out laboratory and induced thermal abuse to cell(s) to simulate a fire caused by a failed cell. The live monitoring of the temperature at different critical points produced key data which are shared with the Flemish Institute for technological research (VITO), who carries out thermal modelling of the packaged lithium cells. VITO’s thermal modelling aims to forecast the propagation of heat across a fully packed box of Li-ion cells which will predict the consequences caused by failed cells.

Furthermore, these ground breaking data contribute towards other innovations related to lithium batteries safety. This includes the interpreting the data for prognostic uses to predict a failure in a battery ahead of time before a catastrophic event.