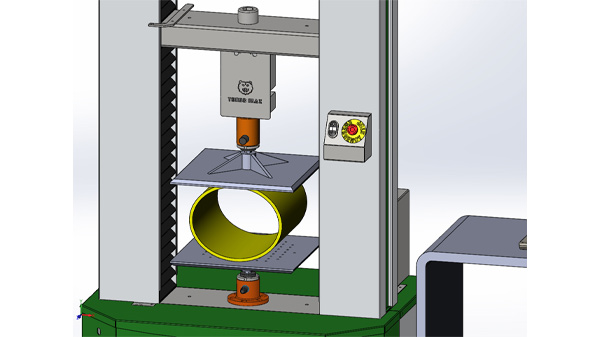

Here, Impact Laboratories are undertaking a ring deflection test on a pipe to determine its ring stiffness and resistance to structural damage.

The test is used to check pipelines, commonly used for wastewater and sewage before they are buried under the ground to measure their resistance to the weights applied to them by the ground structure.

In this test, a section of pipe is subjected to a force to deflect the pipe by 3% of its diameter, and then slowly relaxed over a two minute period. It is then pressed again (in this case to 27mm) at 120degrees rotation, and once again relaxed. This is then repeated at the 240degrees rotation.

After performing the test at three rotations, the average force and deflection are averaged to determine the specific ring stiffness of the pipe.

Finally, at the 240degrees rotation, the pipe is pressed to destruction, or until structural damage such as cracking, delamination or rupture is observed.

Ring Stiffness & resistance to Structural Damage

By performing this test the pipe manufacturer can be sure of the conditions and forces that their pipes will resist in a real-world environment. The relatively low cost of performing this test way outweighs the liability of an infield failure.

Impact Laboratories have over 40 years of experience of carrying out these type of tests. If you have any concerns about your product quality or need similar failure analysis work done, then please get in touch with one of our technical experts.

Head to our social media channels to learn more about what we do and stay up-to-date with recent news: Twitter, Facebook, LinkedIn.