ISO 11507 : Automotive Accelerated Weathering Standards

ISO 11507 – Artificial Weathering of Coatings Using Fluorescent UV Lamps

Sunlight, moisture, and temperature fluctuations can take a serious toll on coatings; causing fading, chalking, cracking, or loss of adhesion. For manufacturers and formulators, the challenge is proving that your coating can withstand years of outdoor exposure before it reaches the market.

ISO 11507 artificial weathering testing provides a controlled, accelerated way to assess how paints and coatings will perform in the real world.

What ISO 11507 Testing Involves

ISO 11507 specifies a laboratory method for artificial weathering of coatings using fluorescent UV lamps and moisture exposure.

The test exposes coated panels to cycles of UV light and condensation, simulating the combined effects of sunlight and dew. It allows you to evaluate how coatings change in appearance, gloss, adhesion, and surface integrity over time.

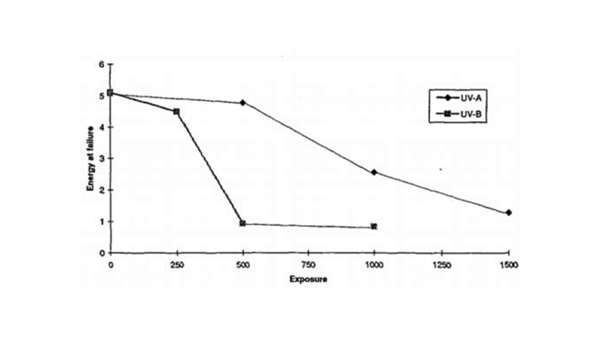

Different UV lamp types may be used, depending on whether you’re simulating outdoor daylight or more aggressive UV conditions.

Methodology

At Impact Solutions, we perform ISO 11507 testing using QUV accelerated weathering chambers, fully compliant with ISO procedures and calibrated for precision.

A typical test sequence includes:

- Mounting the sample inside the QUV chamber.

- Setting UV exposure cycles, such as 8 hours UV at 60 °C followed by 4 hours condensation at 50 °C.

- Monitoring irradiance, sample temperature, and humidity throughout the test.

- Periodic evaluations of colour, gloss, cracking, chalking, and adhesion.

Test durations differ in range, depending on the intended outdoor lifetime of the coating system.

Relevant Industry Applications

ISO 11507 is widely used across:

- Paints and protective coatings for metals, plastics, and composites

- Architectural coatings for buildings and infrastructure

- Automotive finishes and clear coats

- Marine and offshore coatings exposed to harsh UV and moisture

- R&D and quality assurance, to compare formulations and verify UV stabiliser performance

Benefits of ISO 11507 Testing

- Provides accelerated simulation of UV and moisture exposure

- Helps predict long-term coating performance and appearance retention

- Enables comparison of formulations and stabiliser systems

- Reduces product failure risk in outdoor environments

- Supports compliance with international weathering standards and specifications

FAQ

Q: How does ISO 11507 differ from ASTM G154?

Both use fluorescent UV lamps, but ISO 11507 is specific to paints and coatings, while ASTM G154 applies more broadly to non-metallic materials.

Q: What’s the typical test duration?

This depends on product type and required performance criteria.

Q: What can be measured during or after the test?

Common assessments include colour change, gloss loss, chalking, cracking, adhesion, and surface texture.

Want to verify your coating’s durability before it reaches the field?

Contact Impact Solutions to discuss ISO 11507 fluorescent UV testing and how we can help you demonstrate proven weathering performance.