UL94 Thin Material Vertical Burning Test

The test is performed on thin materials which distort, shrink or are consumed up to the holding clamp when tested in 20mm Vertical Burning Test for V0, V1 or V2 classification. This test requires specimens to be wrapped longitudinally around 13mm diameter mandrel.

Specimens: Four sets of 5 specimens with nominal dimensions 200mm x 50mm and in minimum and maximum thickness.

Specimen conditioning:

Two sets of 5 specimens per sample were conditioned as follows:

i. First set at 230C and relative humidity 50% for a minimum of 48 hours.

ii. Second, set in an air circulating oven for 168 hours at 700C and then cooled in a desiccator for a minimum of 4 hours.

Gas flow: Set the methane gas flow to 105 ml/min. Adjust the flow and air intakes of the burner to get a clean blue flame 20mm high.

Flame application: 20mm Bunsen burner flame

Flame application time: 2 x 3 seconds application. The second flame application time begins as soon as the ignited specimen is extinguished or immediately if the specimen does not ignite.

Measurements:

A – Duration of flaming after first flame application (seconds).

B – Duration of flaming after second flame application (seconds).

C – Duration of glowing after second flame application (seconds).

D – Whether or not specimens burn up to the 125mm mark.

E – Whether or not specimens drip flaming particles which ignite cotton swatch.

Based on the measured values use the following table to classify the material as VTM-0, VTM-1 or VTM-2.

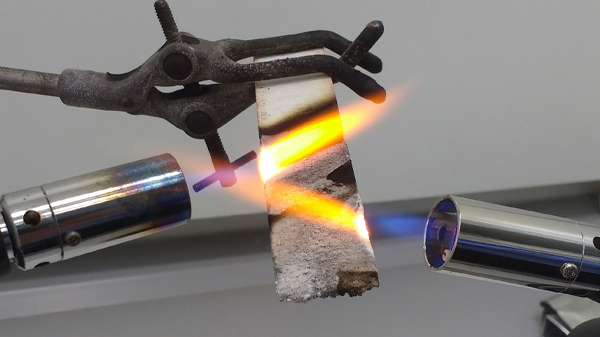

Test setup: The Bunsen burner and test specimen are set up as shown in the following test schematic.