Lithium Ion Battery Transportation

Enhancing safety of lithium ion battery transportation, in accordance with draft standard SAE AS6413

Impact Solutions has expertise in lithium battery (i.e. Li-ion) bespoke testing, with a particular understanding of lithium ion battery transportation. It started when Impact Solutions was invited to join a large consortium project (Project Sabatair) established by the European Commission. This large consortium project is in partnership with the European Union Aviation Safety Agents (EASA), Airbus and many more relevant industrial partners. The project aims to contribute towards enhancing safety when transporting lithium metal and Li-ion on board a cargo or passenger aircraft. It is known that between 2006 and 2011, three cargo aircrafts were lost due to uncontrolled fires that may have been caused by lithium-based batteries. As the volume of lithium battery operated devices increase, the number of incidents rise simultaneously. The current measures are deemed to be inadequate, thus the International Civil Aviation Organisation (ICAO) imposed a ban on lithium ion battery transportation, as cargo, in passenger aircraft until effective solutions are in place.

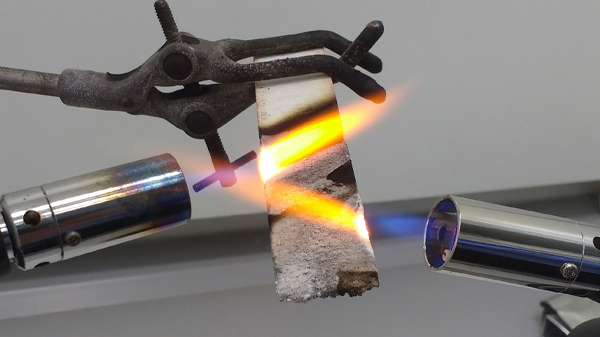

Impact’s involvement in this project is to lead the majority of technical work including validation testing by abusing Li-ion batteries until the cell enters thermal runaway – when a cell, or a region of the cell reaches an elevated temperature due to thermal abuse. The tests carried out are aligned with a standard drafted by the Society of Automotive Engineers (SAE) which is titled SAE AS6413. The test validations comprise of testing 18650 Li-ion cells as well as pouch cells. We have built a battery testing chamber that is in accordance to the SAE AS6413 which allows Impact to abuse the cell in a controlled environment in order to analysis the failure mechanism, battery behaviour, live thermal monitoring of the cell and more. These operations allow the consortium to assess the following:

- Effectiveness of the testing methods described in the SAE AS6413 draft standard,

- Identify and assess additional mitigating measures to packaging

- Evaluate the performance of mitigating measures against fire risk

- Develop guidelines to support the production of a safety risk assessment of operators

Impact Solutions has a comprehensive understanding of the regulatory requirements for transporting Lithium cells (i.e. Li-ion) as cargo on aircraft because we are a member of the SAE G-27 Lithium Battery Packaging Performance committee. The committee aims to produce a standard that demonstrates and documents the control of potential hazards from lithium metal and Li-ion cells or batteries (UN 3090 and 3480) when transported via cargo on aircraft. The SAE AS6413 also addresses the control of hazards may evolve from a failure of cells by containing the hazard within the packaging.

Undoubtedly, this project is a milestone towards the future of lithium batteries as cargo in air transport. Nevertheless, the bigger picture is to collaborate with many industrial leaders to enhance lithium battery safety as a whole which can later be adapted by other industries. Moreover, the data produced throughout the research process in this project are key towards other areas of lithium battery development. The more we understand about the behaviour of this energy storage device, the more we can take advantage of its application and performance.

Figure 1 – Result of inducing thermal abuse to a stack of lithium pouch cells