Impact Solutions, experts in plastic and pipe testing, have been granted subcontractor accreditation by Morrison Utility Services: the UK’s leading utility services provider. Our lab will be offering their highly competitive prices for UKAS accredited destructive testing of butt fusion and electrofusion pipe joints for Morrison Utility Services’ PE pipeline installations. Impact Solutions now offer this service as part of their renewed scope of accreditation for UKAS and have upped their pipe size capabilities to test butt fusion joints up to 1600mm diameter, with wall thickness upto 110mm.

Commercial Manager David Smith said,

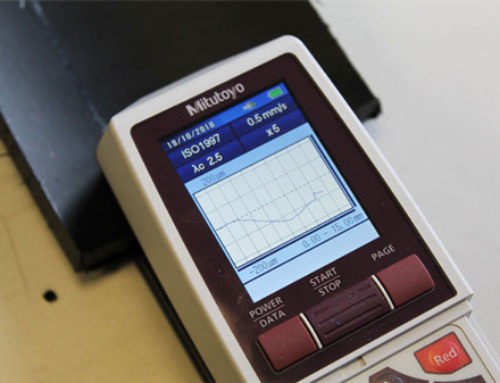

The opportunity with Morrison Utility Services also bolsters the development of Impact NDT, our new technology for non-destructive testing of electrofusion joints on PE pipelines, as we calibrate and carry out NDT assessment on every electrofusion joint that comes in to the lab. Following calibration, Impact NDT can then be used on that make and size of electrofusion joint for real time assessment in the field.

PE pipe joints represent the weakest point of a pipeline and in 2012 a UKWIR report suggested that 20% of electrofusion joints fail before the completion of their intended service life, with poor workmanship and equipment failures the most common causes of failures.

If you have the need for quality control/assurance for any PE pipeline installations to WIS 4-32-08, ISO 13953 or ISO13954 or to find out more about Impact NDT please get in touch with one of our key industry experts.

Follow us on Twitter, Facebook and LinkedIn to stay up-to-date with our progress.