FNCT – Environmental Stress Crack Testing

Impact Solutions is UKAS accredited to carry out full notch creep test (FNCT) to ISO 16770:2004, which is rapidly becoming the preferred way of measuring the stress crack resistance of a polyethylene.

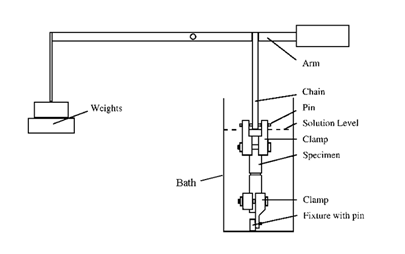

A constant stress is applied to the specimen, most conveniently via a lever arm loading arrangement, and the time for the specimen to fail is recorded. The specimens are generally tested at elevated temperature in a test fluid, which is often a detergent solution to accelerate cracking. The stress level applied to the specimen depends upon the stress crack resistance of the material and the test temperature.

The aim of FNCT is to assess resistance to brittle failure. In order to achieve brittle failure at any given temperature, the applied stress levels must be significantly lower than the corresponding yield stress at that temperature.

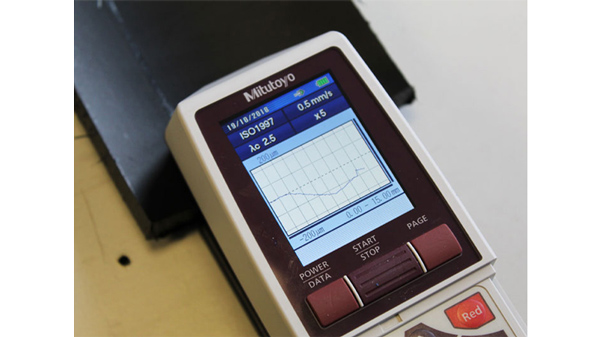

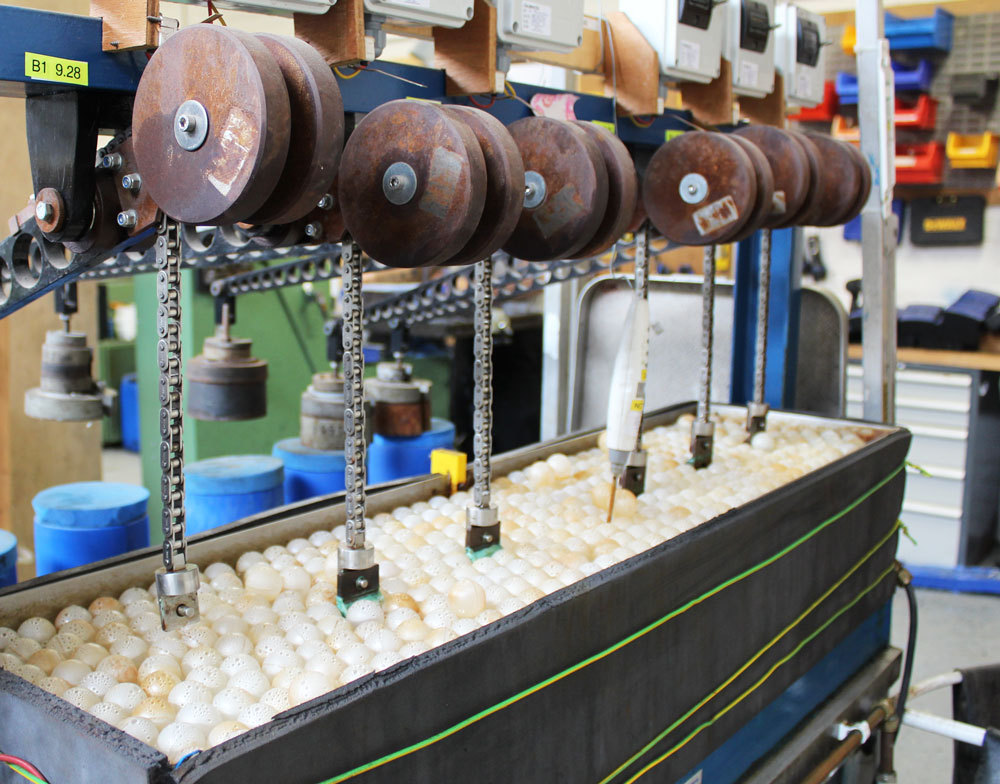

Full Notch Creep Testing Equipment

Impact Solutions have designed their own bespoke FNCT test equipment in order to give highly accurate results. Our equipment design was that used in the original FNCT standard (ISO 16770) as can be seen in the diagram.

We have 24 FNCT stations available for rent and can handle a range of temperatures. The testing can be performed with a wide range of chemical agents in order to simulate stress cracking.

Practical uses of FNCT

impact perform FNCT for a wide range of clients, including pipe specification and material analysis, containers and automotive.