UN Dangerous Goods FAQs

Our usual lead time for testing varies depending on type of material. Plastic drums and jerricans are required to undergo stack testing for 28 days, whereas Fibreboard box and steel drums are shorter times, and we aim to have those completed within 2 weeks. However, this can be accelerated in individual circumstances if required.

Impact Laboratories will prepare a report. Should the package meet all the requirements we will send you the report. We will also supply the report directly to the VCA-DGO along with the application for your marking (you will have to pay the VCA direct for the application fee). If the package fails we will explain to you the failure.

Their lead time varies but is usually around 21 working days. Please note Impact Laboratories cannot accelerate this time as we are completely independent to the VCA.

The VCA-DGO are the competent authority in the UK for the issuance of UN Dangerous Goods markings. This allows them to issue you the UN mark. Any UN mark you see with ‘GB’ at the end has been issued by the VCA as the British authority.

Currently, they offer an accelerated process. The cost is approximately double the usual application route but will mean your marking can be issued in around 48 hours.

No. After testing is complete we will send the report along with an application to the VCA. You will have to pay their application fees directly to the VCA in addition to our testing costs which will be quoted to you directly. Currently, the VCA charge an application fee of £425 and an annual fee of £253.

The number of samples required varies depending on the type of package being tested. As a guide, we usually request the following:

- Fibreboard boxes – 9 sample boxes, complete with inner packaging.

- Steel Drums – 13 drums, complete with all fittings.

- Plastic Drums – 13 drums, complete.

It is always best to provide extra samples if you are shipping them a significant distance as if failures occur it allows us to retest samples quickly without needing to request more.

Packages need to be as close as possible to the finished product. While customer logos are not required, it is always best practice to have the testing completed on an actual product. Should there be any incident into your package while the marking is being used, any variation from the tested package may lead to additional future testing costs. You cannot have any UN Dangerous Goods marking indicated until your certificate is approved.

No. It is perfectly acceptable to ship the boxes flat packed, with the inners in a separate box. If shipping ‘made up’, it is important that you ship inside another box so as to avoid damaging the test specimens.

For fibreboard boxes, you need to supply the tape that is recommended for sealing the box and the inners. In some cases, we may ask you to supply the intended substance to be packaged in the inners if it cannot be substituted with a common inert substance or liquid.

We are certified to test for a full range of model liquids. Model liquids are assigned to groups of chemicals to simulate a wide range of different liquids which may need to be transported.

You are required to test all individual packages and acquire a unique UN Dangerous Goods mark for each one. However, if you can demonstrate that the designs are wholly similar it is possible to apply to the VCA for a deviation to allow reduced testing. This is dictated by the VCA, and although Impact Solutions can liaise with them for the best solution, we must test to the specifications that they set out. If you have multiple packages in your range which you want to be tested, please contact us so we can discuss the best way forward.

Before testing begins we require you to complete the VCA forms. These are the test specification and the Test requirements. The test specification needs to match your manufacturing process as we will compare measurements of the test specimens against your spec sheet. Any variances may lead to your packages failing the testing.

Yes and No. Your package can be UN Dangerous Goods marked, however only a UK based entity can hold the certificate. Impact Solutions offer a certificate holding service for non-UK based companies to enable them to get UN Dangerous Goods marking. The certificate is held in the name of Impact and assigned to yourself. You will be required to sign a guarantee to be held by the VCA that you will be responsible should any investigation of the UN marking be required.

If your package fails while using the UN marking, the VCA may require testing to determine the reason for failure.

Your marking is valid for 5 years.

You are required to do a revalidation test. This involves simply a spec check of a submitted sample. Your marking will be revalidated if it conforms to the specifications of the originally tested package.

If your package fails revalidation you have a few options: Liaise with the manufacturer and investigate the reason for failure, and submit a new package for a 2nd revalidation. Apply for a new UN Dangerous Goods marking.

Revalidation failures occur in a significant number of packages. Normally this is caused where a manufacturer has substituted a new material during the five years since the original testing. Even a small change can cause a failure.

Yes, water is a pre-requisite for testing, before proceeding to testing on model liquids.

Blog

UN Drop Testing

ImpactSolutions2024-04-11T15:26:27+01:00April 11th, 2024|

Testing to Prove Sustainability Claims

Nikki Caldwell2024-01-24T08:54:11+00:00January 24th, 2024|

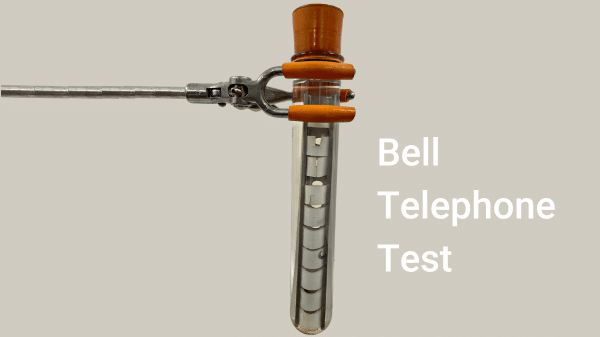

Bell Telephone Test | ESCR

ImpactSolutions2023-11-23T14:45:18+00:00November 23rd, 2023|

Resin Fingerprinting

Nikki Caldwell2023-04-18T15:48:30+01:00April 18th, 2023|