The importance of accelerated weathering testing can never be underestimated. The knowledge of how your products will perform years into the future allows you to confidently offer longer term warranties to your customers, beating those of your competitors. Weathering testing can also protect you from expensive lawsuits should your products fail in the future.

While resin suppliers will supply data sheets and explain what their specific resins can be used for, how the manufacturer handles that resin can be key to the final product. Even small variances in heating and cooling rates during the moulding process can create huge differences in the environmental stress crack and weathering testing performance of products.

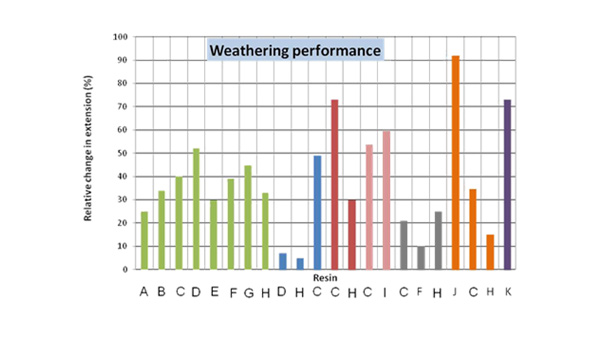

The below graph produced by Impact Solutions illustrates this with the performance of different tank grade materials used by different moulders to make tanks, which we then tested.

The different colours represent a different resin. The ‘green’ resin was used by moulders A, B, C, D, E, F, G and H. As you can see all the moulders produced a product with different % change in extension. You can also see how different moulders performed better with different resins. While moulder ‘D’ produced a product with the green resin which exceeded the 50% fail rate, using the blue resin they produced a product which showed very little change after weathering.

Why does this happen and the importance of weathering testing?

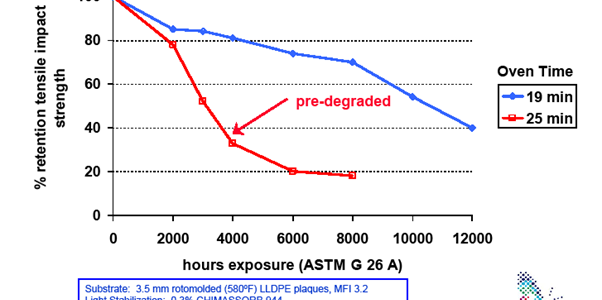

The weathering performance of the polymer can be affected in a number of processes used by the moulder. The below graph illustrates this, undertaken in test conditions. Two different plaques were pressed, using the same material. One plaque was heated for 25 minutes, while the other was heated in the oven for 19 minutes.

Despite the plaques being of an identical material, they performed very differently when tested for impact strength after accelerated weathering was complete.

The above graphs demonstrate no matter how good a resin you are provided, how you handle it and how you process it will ultimately determine the strength and longevity of the product you make.

Impact Solutions is able to undertake accelerated weathering testing using its Q-Sun weatherometer. This simulates the conditions of a Northern European climate, allowing Impact to age your product at around 8x’s normal time. Therefore, 3 weeks in the weatherometer can simulate performance in the field after 6 months. Times can be adjusted to suit the climate you are trying to simulate, or simulate indoor conditions instead of outdoor.

To find out more about how Impact’s knowledge can help you build a better product, and how we can help you avoid costly future bills, get in touch with any of our experts.

Why don’t you give us a follow on Twitter, Facebook and LinkedIn.