Plastic Identification is important as plastics are synthetic or semi-synthetic materials used in a huge and growing range of applications. The building blocks for making plastics are long hydrocarbon chains (polymers) sourced mainly from the crude oil or natural gas. There are many types of different plastics and plastic identification is crucial to understand plastics in mixed waste streams.

Look around you and chances are high that a variety of the things you can see are made of plastics. In fact, every activity nowadays is affected by plastics and many depend entirely on plastic products. For example in cars: synthetic bumper, dashboards, steering wheels and switches; in medicine: plastic hypodermic syringes and artificial hip joints; in telecommunications: telephones, circuit boards and cable insulation and in many other applications such as sports equipment clothing, optical discs, television and cinema.

All these plastics are made from the essential polymer mixed with a blend of materials known as additives. Additives, play a key role to the performance and behaviour of the plastics, turning them into tougher, harder, long-lasting, fireproof and more colourful products. Additives are usually inorganic materials such as minerals, metals or halogens.

Although most of the additives aim to enhance the properties of the plastics, they might also cause serious problems to humans and to the environment. Many of the additives when burnt release poisonous gases, others react aggressively with the soil and water turning them into potential time bombs for the environment and not suitable for recycling or disposal. Many of these additives such as the brominated flame retardants are now tightly regulated by the European Union through the WEEE (Regulation of waste disposal for electronic and electrical equipment) and RoHS (Restriction of the use of certain hazardous substances in electrical and electronic equipment) legislation. On top of that Children’s plastic toys using phthalates as plasticisers (to soften the plastic) have been banned from the markets of many countries due to adverse health effects.

As a result, new plastic materials are produced with more environmental-friendly and safer compounds. However, the big problem has now transferred to the recycling of the contaminated plastics. The recycling companies and the recycled plastic compounders/designers/moulders must be able to determine the overall contamination of their plastic materials. The plastic identification of the hazardous parts was thought to be a very costly and slow process discouraging many of them to recycle and reuse their waste plastics, with serious direct implications to the environment.

Plastic identification of waste plastic materials has recently become a few seconds process with the use of high-performance state-of-the-art Fourier-Transform Infrared (FTIR) spectrometers. The principle of FTIR spectroscopy lies on the ability of the molecules to absorb infrared radiation at a characteristic wavelength, generating an absorbance spectrum unique for each substance (like a fingerprint). Thus, unknown substances could be identified within the specimens by analysing and comparing the spectrum of the virgin (reference) and the spectrum of the contaminated plastics. More precisely, the harmful compounds within the plastic samples show significant absorption bands in the IR region (2000 cm-1 to 600 cm-1), enabling a fast qualitative identification.

The key to provide fast and straight forward sample IR testing is the advanced Attenuated Total Reflection (ATR) technique (fig with ATR). The sample (just a small piece of plastic needed) is being tested without requiring any prior sample preparation, by simply pressing it with the pressure clamp onto the surface of the ATR crystal. Subsequently, the IR radiation penetrates a few microns into the sample and the detector of the FTIR spectrometer analyses the radiation absorbed by the sample.

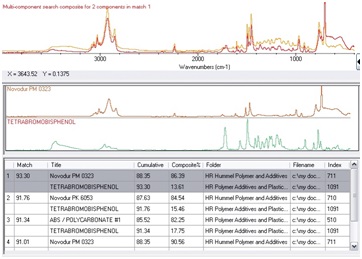

The fast and straight forward spectra collection using the ATR–FTIR technique is being coupled with the development of novel and sophisticated FTIR software able to analyse reference spectra from databases and identify the polymer (plastic identification) and the additives used. For example, a small piece of plastic from a computer monitor was tested using a Thermo Scientific Nicolet iS10 spectrometer with the ATR diamond accessory. The spectrum obtained was analysed using the advanced OMNIC Spectra software.

Initial spectrum analysis with OMNIC, using reference spectra databases revealed that the basic absorbance peaks of the sample match with the ABS/PC copolymer’s, with a match value higher than 90%. However, several small unmatched peaks between 1000 and 1400 cm-1 have been also identified. Further spectrum analysis, showed that these peaks correspond to the banned additive Tetrabromobishenol (TBBP), widely used as flame retardant (Fig.1). As a result, FTIR analysis coupled with the ATR attachment and the advanced software offered an incredible advantage of identifying hazardous compounds from waste plastic components very fast, accurately and with the minimum sample preparation.

Fig.1 FTIR spectrum analysis of the ABS/PC sample contaminated with TBBP using the OMNIC software. (Figure obtained from Thermo Scientific)

At Impact Laboratories, we are an independent testing, R&D and consultancy laboratory, equipped with the Thermo Scientific iS10 FTIR spectrometer combined with the ATR attachment. We offer immediate solutions to our customers who want to obtain a full and accurate plastic identification of their products. Every day we are using FTIR to analyse products, and do plastic identification from the Recycling Industry and from Moulders. For higher consistency, we are also equipped with a latest technology Differential Scanning Calorimeter (DSC). FTIR results are coupled with the results of the DSC yielding remarkable qualitative and quantitative details on the plastic additives and purity. Finally, what makes Impact unique from other laboratories is that analysis of the results is being conducted by polymer technologists and scientists with more than 40 years of experience in the plastics petrochemical and recycling industries. Impact do not just provide test results, we also provide ideas and suggestions on how to achieve the best value for your products and how to make the plastic industry more environmentally friendlier and safer.

To learn more about Impact Laboratories and how we do plastic identification, contact us today!

Be sure to also give us a follow on Twitter, Facebook and LinkedIn.