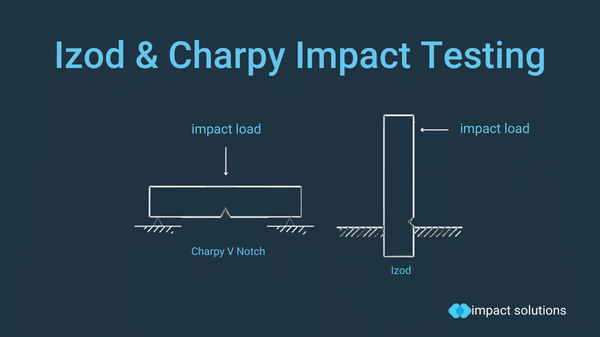

IZOD Impact Test

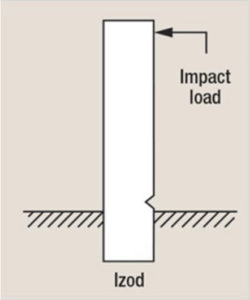

The IZOD impact test is suitable for notched and un-notched specimens, where the specimen is positioned vertically. The test method investigates the behaviour of plastic/composite materials under the specified impact conditions. This also allows the estimation of the brittleness or toughness of the specimens, taking in to account the limitations within the test conditions.

Impact Solutions are UKAS accredited to conduct ISO 180:2019 and can also conduct ASTM D256.

Izod impact testing is suitable for a diverse range of materials. This may include ridged thermoplastic moulding/ extrusion materials (filled and unfilled), fibre-reinforced composite (unidirectional or non-unidirectional) and thermotropic liquid-crystal polymers etc.

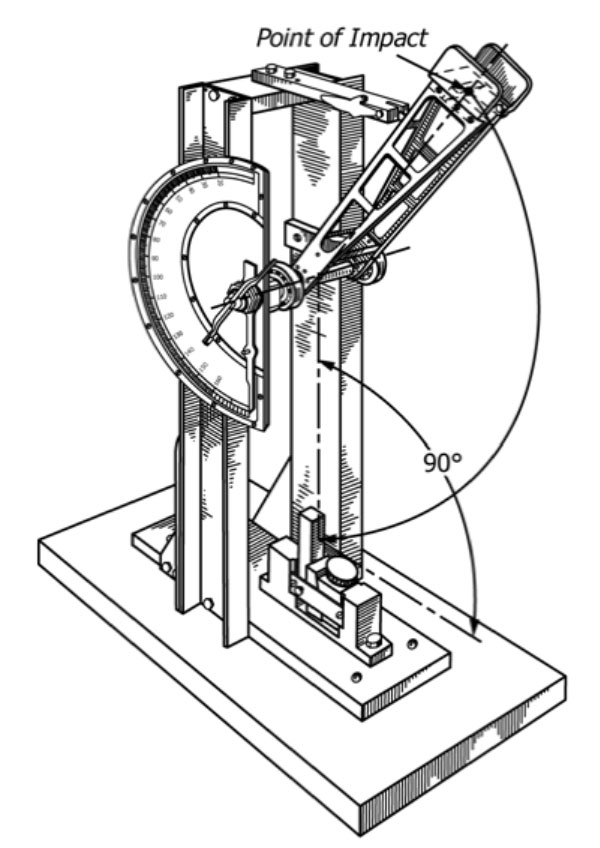

An IZOD Impact Tester contains a pendulum type hammer with a striker and a mount to clamp the specimen into position. As the pendulum strikes the specimen, the breaking energy of the specimen is recorded. The frictional losses and the absorbed energy of the specimen can be determined using ISO 13802. Impact testing simulates the condition at which the sample is expected to operate in. Impact Solutions can condition samples to sub-ambient temperatures if required.