There are numerous products entering the market that claim to be flushable. From sanitary products, to wipes and medical bandages, but do they really break down once they are flushed away?

What is flushability testing?

In a world where consumer convenience meets the growing concern for environmental sustainability, the evaluation of flushable products has become extremely important. Despite the push for eco-friendly solutions, the demand for easily disposable products remains prevalent among many consumers. This dynamic landscape has prompted the development of flushability testing or scientifically known as, biodisintegration testing. Using industry standards that have been designed to replicate the harsh conditions prevailing in sewerage and wastewater treatment systems, businesses can ensure that their flushable products can hold up to the challenges of disintegration in these environments.

Understanding the Testing Process

Following industry standards such as EDANA FG 505/506 R1, the precise timeframes and disintegration levels that products must meet to qualify as flushable are evaluated including scenarios of aerobic and anaerobic conditions, mirroring the diverse environments during the wastewater treatment process. Part A of biodisintegration testing involves subjecting product samples to incubation in a biologically active solution sourced directly from a wastewater treatment facility. Strict protocols regulate the handling, transfer, and storage of these samples within reaction vessels to replicate either aerobic or anaerobic conditions. Maintaining the right temperature is crucial, and it’s adjusted to meet the requirements of the specific condition.

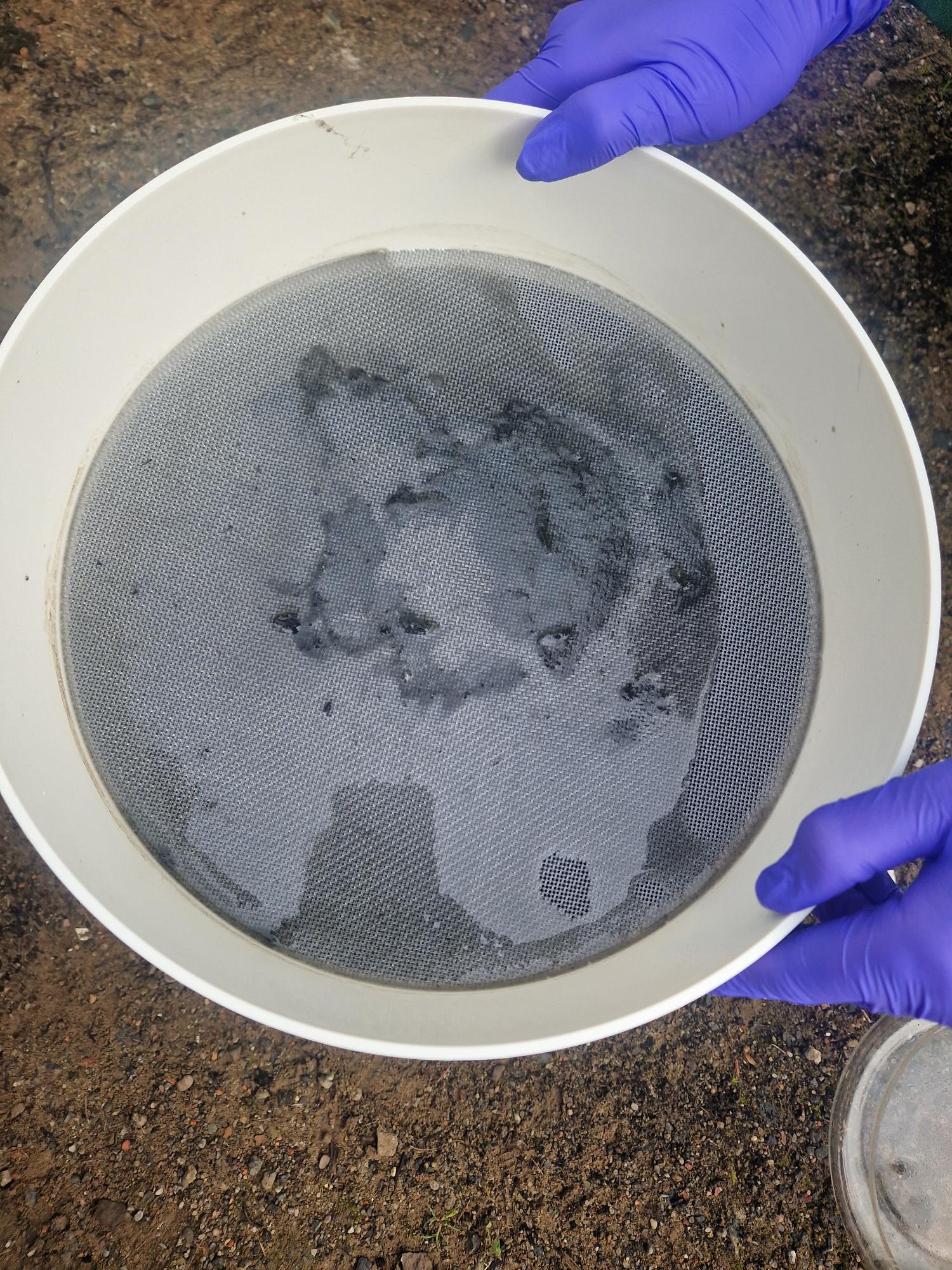

Once the designated time period elapses, the contents of the reaction vessels undergo sieving through fine mesh filters. This step isolates any breakdown  fragments larger than the defined pass criteria. The collected material is then weighed to determine the extent of product disintegration.

fragments larger than the defined pass criteria. The collected material is then weighed to determine the extent of product disintegration.

These stringent testing procedures pave the way for the development and marketing of flushable products that align with environmental sustainability, assuring consumers of their eco-friendly disposal.

What are the guidelines to market flushable products?

In the UK, there are guidelines and regulations regarding the marketing of flushable products. While there isn’t a legal requirement for mandatory testing of flushable products before they’re sold, there are industry standards and guidelines that products need to meet to be labelled as “flushable.”

Manufacturers are encouraged to comply with the Water UK standard, which outlines specific criteria for flushability, ensuring that products labelled as such break down and disperse appropriately in the sewer system without causing blockages or environmental harm. It’s crucial for manufacturers to conduct appropriate tests to ensure their products meet these standards and are genuinely flushable. Failure to meet these standards might lead to dissatisfied consumers, potential environmental issues, or even legalaction against you if the product causes problems in the sewage system.

While there might not be a legal obligation for testing, adhering to industry standards is essential for the credibility and marketability of flushable products in the UK.

Please contact us if you wish to learn more about how we can help you.