Lithium Battery Testing – Cell-Gas

Bespoke testing Case study: Cell-gas / Cell-condensate

The rise of electric vehicles in the current market signifies that ensuring the safety of Li-ion batteries is paramount. Our client from the automotive industry approached us to evaluate the impact of Li-ion cell-gas / cell-condensate on plastic material (typically the material for battery casing). There are no existing standardised procedures to reach such conclusions. Impact has experience and involvement with lithium battery safety projects where our expertise allows us to design bespoke test plan accordingly.

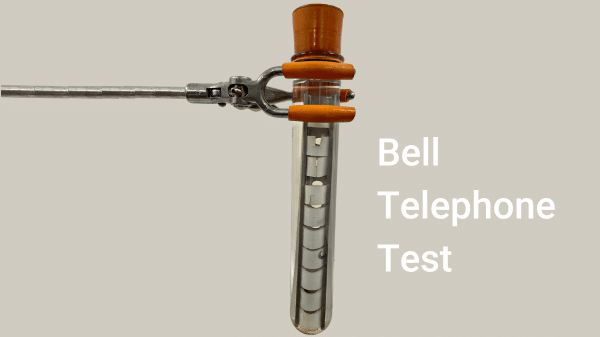

In this scenario, we have combined our expertise in lithium-metal and Li-ion as well as our knowledge in pneumatics to create a bespoke gas encapsulation rig for our client. Where this test can be carried out in a controlled environment and we can dictate the type of thermal event we desire to induce gas release of the Li-ion cell and then encapsulate the gas and condition the client’s sample with the cell-gas or the condensate.

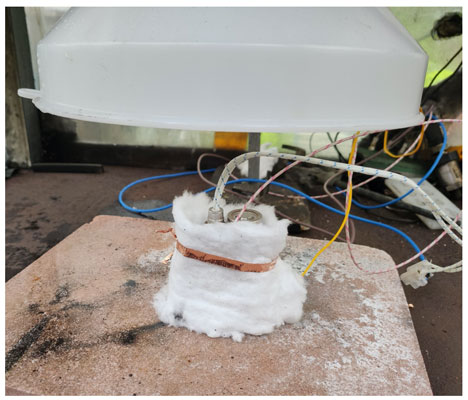

Impact has built a bespoke testing set-up to accommodate out client’s requirement. We are experienced in inducing thermal abuse to Li-ion cells in a controlled manner. In this test, we set-up the appropriate heating module to apply heat to the cell along with live temperature monitoring which will allow us to predict the thermal event. Once we recognise when the critical failure will occur, we can start the encapsulation process to extract the cell-gas required for conditioning the samples. Firstly, we modified two tempered glass containers to act as the contraption to encapsulate the vented cell-gas where the samples will be placed directly into the container as the gas is suction through. Furthermore, we have a similarly modified tempered glass container but it is filled with de-ionised water which will act as a gas trap. The purpose of the second container is two-fold, it acts as a gas trap to minimise any lithium battery gas (which contains traces of hydrogen fluoride) from leaking into the environment or being exposed to operators. Secondly, the gas will be dissolved into the water and form a condensate which is used as the second conditioning parameter of the test. This condensate is collected and later apply onto the samples for conditioning.

Our technical team will assess the effects of the cell-gas on the samples by carrying out tensile testing (ASTM D638 or ISO527) using our Universal Instron tester 3382 machine on the samples. The results of the non-conditioned and post-conditioned samples will be compared. Additionally, we tested the fire-resistant properties of the non-conditioned and post-conditioned samples by executing the UL94 standard test. The combined testing methods provide a comprehensive indicator of the effects of Li-ion gas on the plastic material, by highlighting the key property requirements. This type of bespoke testing is only possible with the appropriate expertise and experienced, where our team can think outside the box to provide solutions to our clients.

Figure 1 – after thermal event

Figure 2 – battery under thermal abuse for venting and a hood is placed directly above to capture the gas