Fracture Toughness Testing Capabilities

Impact Solutions is well equipped for fast fracture testing with the addition of an IFWI tester, adding fracture toughness determination to our list of available tests. Our impact capabilities are now:

- A pendulum impact tester for standard Charpy and Izod impact tests such as ISO 179 & 180

- An instrumented falling weight impact tester (IFWI) for fracture toughness determination e.g. BS ISO 17281.

With this equipment, Impact Solutions is well-placed to support its clients. Here’s why:-

The mechanics of fracture toughness

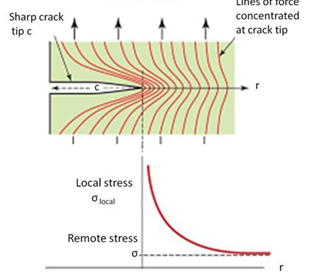

The fracture toughness of a material results from a crack propagating through the material. The development of a crack can occur over time, slow crack growth, or instantaneously, fast fracture or impact. Charpy impact and Izod impact are two tests undertaken using a pendulum impact tester. These tests are usually used for ranking or acceptance tests. They do not however measure a true material property, meaning one that is independent of size and shape of the sample, so the values do not help with design. To get a real underlying material property we need the idea of stress intensity and fracture toughness from the theory of Linear Elastic Fracture Mechanics (LEFM), the basic theory of fracture developed by Griffith and Irwin. Cracks concentrate stress. A remote stress σ applies a force that is transmitted through a crack tip as shown in Figure 1 resulting in the local stress around the crack tip increasing.

Stress concentration around crack-tip

The stress intensity factor KI is a measure of the intensity of the local stress and is given by

K1 = Y σ √πc

Where,

- Y = constant dependent on the sample geometry – (unitless)

- σ = remote stress (MPa)

- c = crack length (m)

Cracks propagate when the stress intensity factor exceeds a critical value – the fracture toughness K1c. Fracture toughness is a material property which means it is independent of the way it is measured and so is useful for product designers. Another material property often used by designers is the energy release rate derived from the energy to break a sample. When a sample fractures two new surfaces are formed and as surfaces have energy (the surface energy ϒ) it takes external work to create them. The energy release rate G ≥2 ϒ as two surfaces are formed during fracture. It takes much more energy than 2 ϒ because of the plastic deformation around the crack tip. Growing a crack therefore costs energy G c J/m2 to form the two surfaces. G c is called the critical strain energy release rate or sometimes confusingly the toughness. K1c and G c are related through the modulus as shown below

K1c = √E G c

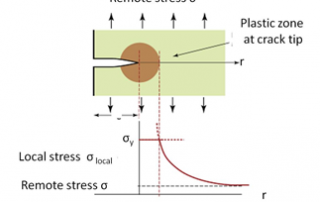

The crack-tip plastic zone

The intense stress field at the tip-of-the-crack generates a plastic zone, or yield zone, in polymers.

Plastic yield zone at the crack tip

The size of the zone is given by

ry = K12

πσy2

- When cracks are small materials tend to yield before they fracture but when cracks are large the opposite is true.

- At low temperatures, the yield stress σy – and the zone is reduced and the crack propagates more easily

- Glassy materials tend to be more brittle and prone to brittle cracking

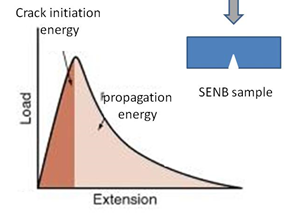

A general load v extension curve for an impact test is shown below together with a single edge notch bend test (SENB) specimen. For ductile impact behaviour the propagation energy part of the curve is quite large but for a brittle fracture, it becomes very small or disappears, leaving the triangular darker region. In the brittle case virtually all the energy goes to initiate a crack and very little to propagate it through the material which shatters.

Typical load v extension curve during impact

Impact fracture toughness facilities in detail

Pendulum Impact Tester

The impact tester is a United Test system designed for Charpy (ISO 179) and Izod (ISO 180) impact tests. To meet these standards the equipment is supplied with;

- Charpy hammers of 1, 2, 4, 7, 15, 25 and 50J and impact velocities of 2.9 and 3.8m/s.

- Izod hammers of 1, 2, 5.5,…….. and impact velocity of 3.5m/s.

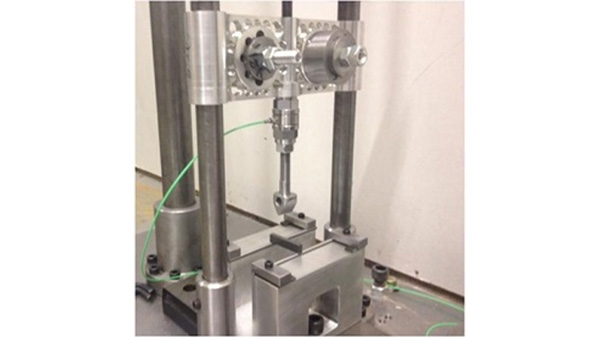

Instrumented Falling Weight Impact (IFWI) Tester

This is an in-house designed instrument with the following capabilities;

- Drop height of up to 3 m delivering impact velocities from 1m/s to 7.7m/s

- Mass of 0.5kg to 7.5kg delivering energies from 1J to 225J

- 20 kN load cell

- Sample holders for (i) single-edge notched bend test (SENB) and (ii) puncture impact and (iii) 120-degree ‘V’ block for pipe impact tests.

- Load v extension graphics

IFMI testing with 1kg mass and SENB assembly

Low-temperature testing

Impact Solutions can undertake sub-ambient tests down to -50oC with the use of an environmental chamber cooled with carbon dioxide, or further using nitrogen and other gases. Get in touch with Impact today, to explore how our expertise and equipment can help you develop superior products, or learn how to prevent failures in existing ones!