Abrasion Wear Analysis of Plastics (Taber Abraser)

Resistance to abrasion is defined as abrasion wear analysis, the ability of a material to resist a mechanical action such as rubbing, scraping, or erosion. One of the most popular methods to determine plastic resistance to abrasion is the Taber Abrasion. Abrasion wear analysis can be difficult to compare but haze variation or weight loss are often evaluated.

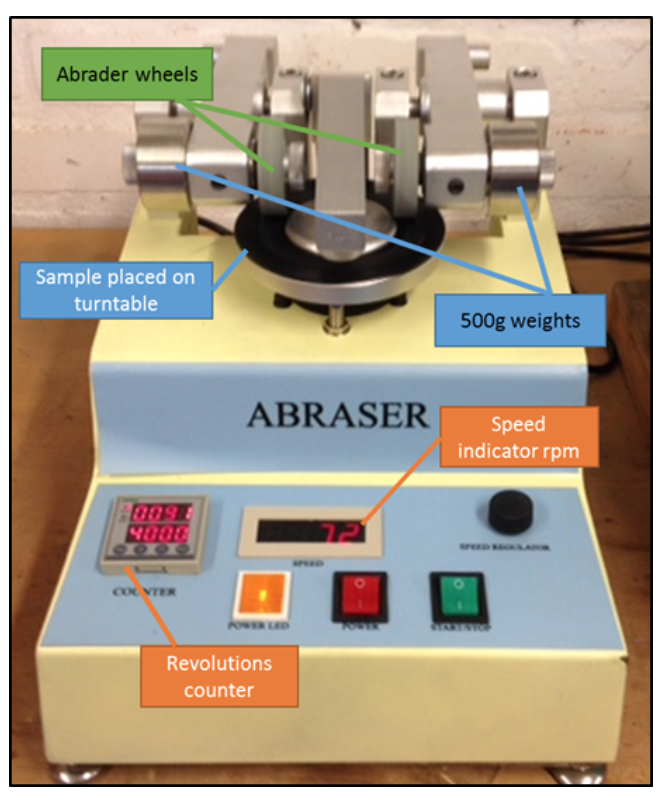

Taber tests (ASTM D1044, D4060, ISO 23794) involve mounting a specimen (typically less than 12.5 mm thickness) to a turntable platform that rotates at a fixed speed. Two GENUINE TABER abrasion wheels, which are applied at a specific pressure, are lowered onto the specimen surface. As the turntable rotates, the wheels are driven by the sample in opposite directions about a horizontal axis displaced tangentially from the axis of the sample. One abrading wheel rubs the specimen outward toward the periphery and the other, inwards towards the centre while a vacuum system removes loose debris during testing.