Quality Assurance and plastic pipe weld testing during installation is a regular part of Impact’s work. We work with some of the largest civil engineers in the country to ensure the quality and longevity of pipe systems throughout projects in the UK. Our work includes pre pipeline specifications, training, auditing and inspection (in conjunction with our partners) as well as destructive and non-destructive quality assurance plastic pipe weld testing, especially butt fusion joints.

While often overlooked, using simple and cost-effective quality control can save millions in the long run, and protect the reputations of civil engineers and contractors alike.

A question often asked is why, after the pipe weld testing are you saying our pipe weld has failed?

All the pipe weld testing is performed in accordance with either WIS standard 4-32-08 or ISO 13953. These standards set down how pipe joints are to be tested and what will constitute a failure.

WIS Standard 4-32-08 for butt fusion weld testing

The WIS standard (which this article will focus on) states;

- The failure mode of all samples should be ductile

- This should be checked by visual inspection of the failure surfaces

- Pull curves can give indications of the failure mode;

- Brittle

- Mixed mode (Brittle/Ductile)

- Ductile

As noted above, there is two ways of assessing the integrity of a weld, and when making the decision on whether to pass or fail according to the WIS standard, both must be taken into account.

Below are three pictures of pulled butt fusion weld joints. One shows a clear brittle failure, which is a fail. The one on the right shows a clear ductile sample, which is considered a pass. The middle joint shows what we call a ‘mixed mode’ failure. This is where part of the sample is brittle, but other areas are ductile, and it is these types of ‘failures’ which cause the most debate.

Sample 7-1017 shows a Brittle Failure. Note how smooth the surface is.

Sample 3-1017 shows a ‘Mixed Mode’ failure. This is where part of the weld interface is brittle, but other areas are ductile. You can see the ‘ductile’ behaviour at the edges, while the centre is smoother with little or no ‘pulling’.

Sample 3-1024 shows a fully ductile sample. This shows that the weld is strong and should perform comparatively with the pipe material itself. Note how the plastic is drawn into peaks (sometimes referred to as fibrils)

The other factor which has to be taken into account when determining the strength of a butt fusion weld is the data produced from the tensile testing. A pipe weld is cut into a number of sections around the weld interface, and the shaped dumbbells pulled by a tensile machine, such as our Instron machine.

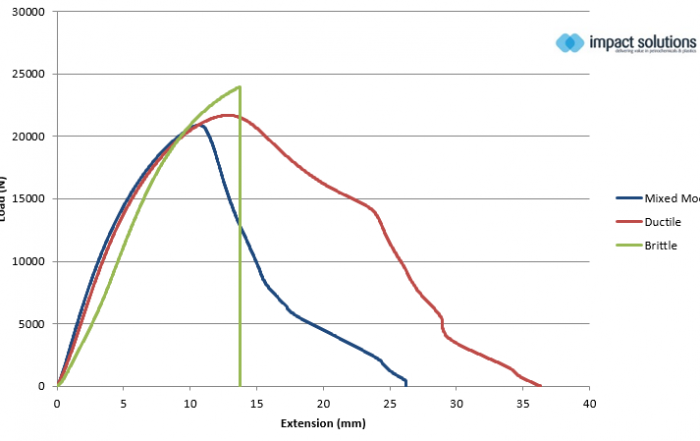

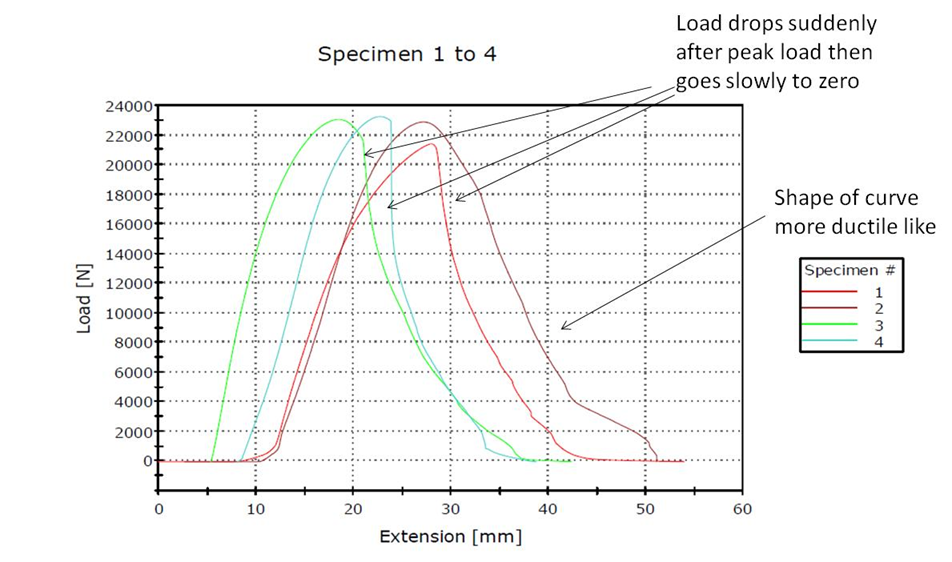

Typical load-extension curves for the different failure modes are shown below:

In green we have a graph for sample 7-1017. The green curve shows a typical brittle fracture. The load initially increases with extension but suddenly drops to zero as a fast fracture is initiated at the weld interface and the sample break with a bang.

The red curves shows typical ductile behaviour. Here the load reached a peak at which time localised voids are beginning to develop in the centre of the sample. However, unlike the brittle failure a fast fracture is prevented by the material between the voids becoming drawn out into fibrils and the load falls to zero slowly as the fibrils gradually fail.

The blue curve shows typical curves for a ‘mixed mode’ brittle/ductile failure. Again, the load increases to a maximum at which time voids form but grow rapidly with a sudden reduction in the load. However, unlike the brittle failure the load does not drop straight to zero because the outer layers are sufficiently welded to prevent a fast fracture developing across the whole interface. After this initial fall the load drops more slowly, with extension further in a ductile manner. It is these mixed mode failures which cause the most debate, as there is a fine line between what constitutes a pass and what constitutes a failure.

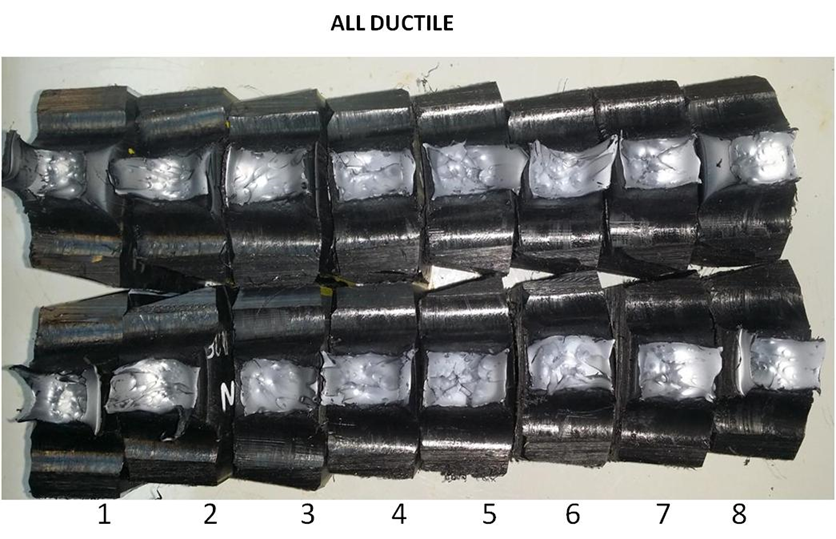

This is what a fully ductile pipe weld should look like. The weld, which is sectioned into 8 parts, are all pulled separately. To pass, all 8 sections must be fully ductile in accordance with WIS – 4-32-08 standard.

This picture clearly shows the ‘pulling’ of the pipe material as the weld is pulled apart. Click on the picture above for a higher definition.

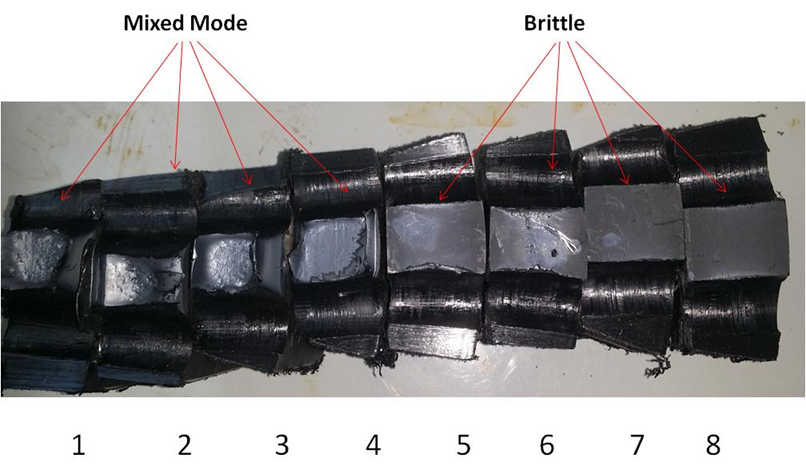

Next we have a pipe weld which has failed. 4 of the samples are considered mixed mode, and the other 4 are brittle.

Below is the graphical data for pulled samples 1 through 4.

What do you notice?

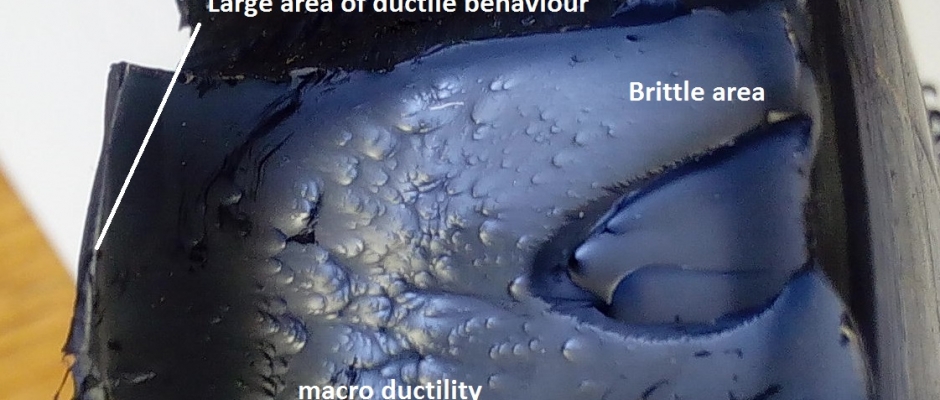

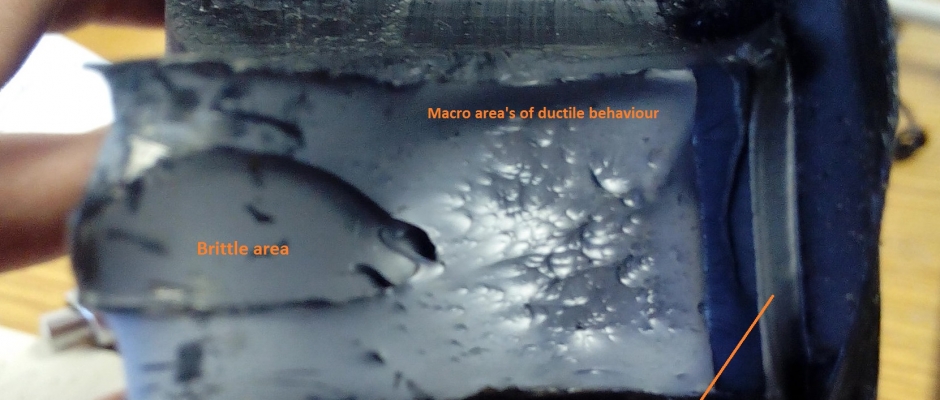

From this graph alone, samples 1, 3 and 4 are clearly displaying mixed mode characteristics. But look at curve #2. It is more symmetrical and displays the type of hyperbolic curve you would often expect from a ductile sample. Without seeing the photographs you may automatically decide that specimen 2 was ductile. But let’s look at sample 2 close up again.

As can be seen, close up, these samples display all the characteristics of a mixed mode failure. Large regions are smooth, while others show small marking known as ‘micro ductility’ where the joint has started to ‘pull’ before snapping prematurely. However, there are large areas at the side of the weld where it has been pulled in a fully ductile manner. What has happened in this case is that this material at the sides has been strong enough to ‘mask’ the brittle and mixed mode failures.

This is why the WIZ 4-32-08 standard insists that both the butt fusion weld interface is visually examined, as well as taking account of the data from a pull test, as this will allow a true determination of the weld’s strength.

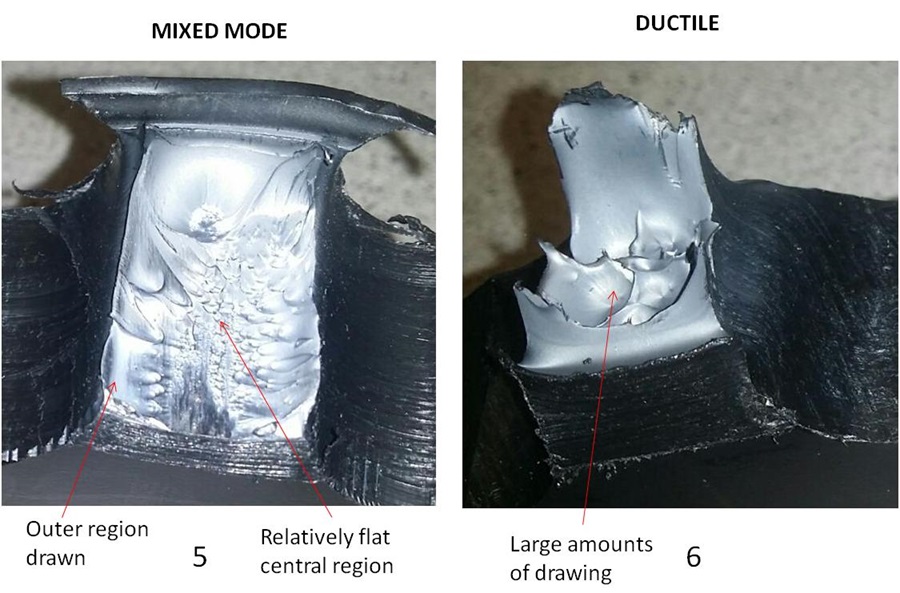

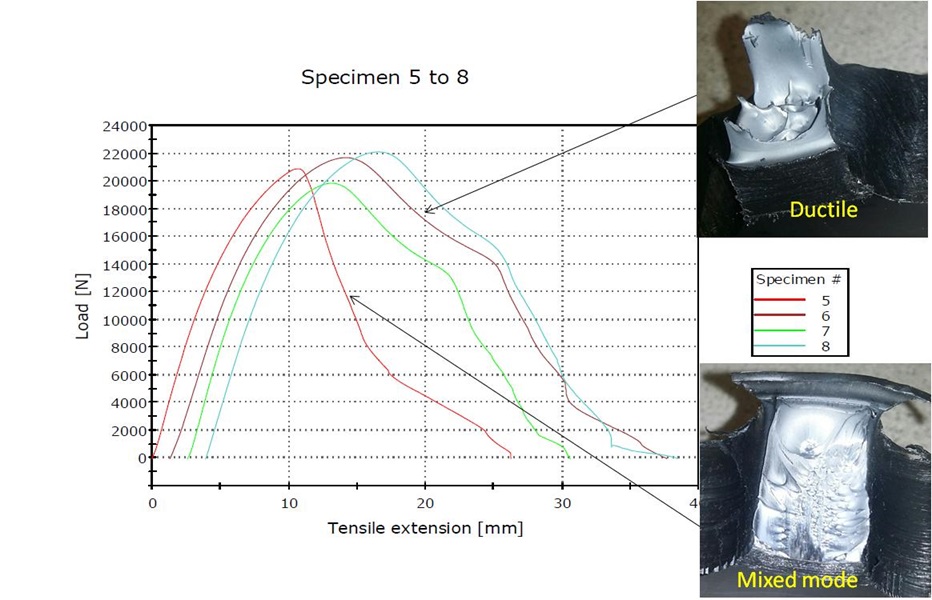

However, it is not always that clear cut. The picture below shows 2 pulled welds. Sample 5 has been determined as mixed mode, while 6 is clearly ductile.

For a weld to pass all the sections must be fully ductile, and this is where an interpretation can make all the difference. For this particular weld, 7 of the samples were clearly ductile, but sample 5 displays a different appearance.

While a large portion of weld 5 shows ductility, it is clearly different to the other sections, especially when compared directly against 6 as above. While it looks like it may be ductile, as we have learnt before we need to examine the data as well.

In this graph, you can clearly see that sample 5 has a different shaped curve to the rest of the samples. This, when combined with the visual appearance shows that the material has not performed the same way as the other 7 samples, and therefore in accordance with WIS 4-32-08 you cannot consider the butt fusion weld fully ductile. This, therefore, constitutes a failure.

Upon closer inspection of the weld interface on sample 5 it became evident that small ‘particulate’ contaminates were present in the brittle area, and thought to have initiated a mixed mode failure.

Impact Laboratories are a leading independent test house, with a specific speciality in butt fusion weld testing and pipeline integrity. We are trusted by some of the largest engineering firms in the country to undertake quality assurance testing, training and provide support and advice. Whether you want to ensure the integrity of your pipeline installations – whether large or small – or have suffered a catastrophic failure from a previous project, Impact Solutions are well placed to help. Turnaround times can be measured in hours & days to ensure you don’t have hold ups in your construction projects.

For more information contact a member of our team today!

Be sure to also follow us on Twitter, Facebook and LinkedIn.