Charpy Impact Test

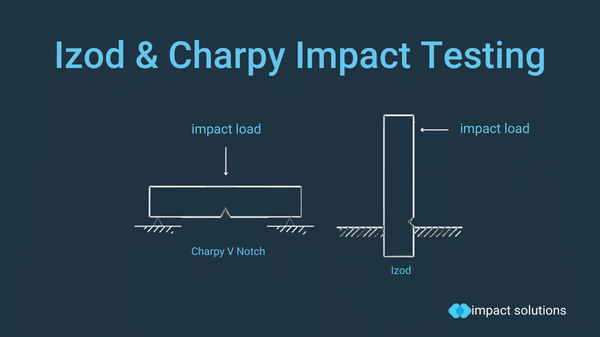

There are two main types of impact testing using a pendulum, IZOD Impact testing and Charpy Impact testing. The two methods are relatively similar but they are mainly distinguished by the difference in the positioning of the specimen. Charpy Impact is defined as the kinetic energy required to initiate fracture and continue until the specimen is fractured completely.

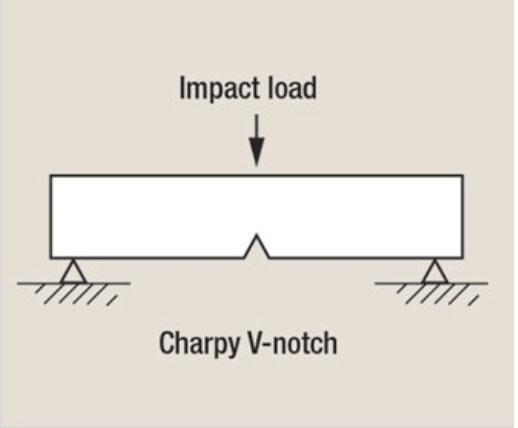

In a Charpy impact test, the specimen (notched or un-notched) is mounted horizontally and supported but unclamped. One of the main purposes of impact testing is to test the material’s toughness. A material’s toughness indicates the amount of energy the material is able to withstand before complete failure. In other words, it is the amount of energy absorbed by the material.

Briefly, the Charpy Impact test holds the sample horizontally with the notch facing away from the pendulum. The pendulum of the Charpy Tester is released and aimed to strike the specimen. If the specimen does not break upon the impact, a heavier pendulum hammer is used until breakage occurs. Eventually, the impact performance of the plastic/composite material is recorded by a fracture toughness measurement, which is calculated from the total energy of fracture divided by the fracture area.

Impact Solutions are UKAS accredited to conduct ISO 179-1:2010 and can also conduct ASTM D6110.