How Accelerated Weathering Works

To test real-world performance, you need to replicate real-world conditions. However, waiting 10 years for results is not commercially viable, and so accelerated weathering is used to ‘accelerate’ the effects of real-world weather.

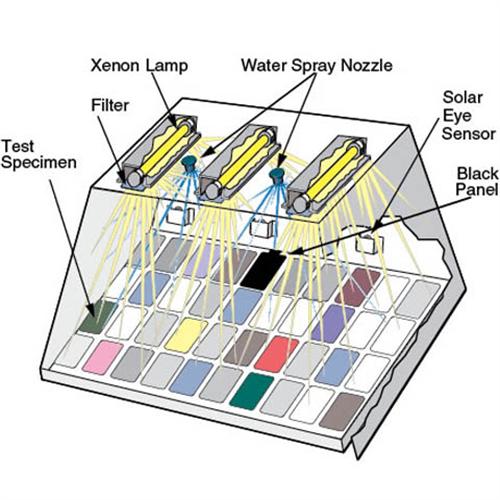

Using a mixture of UV exposure and environmental conditions (spray, moisture and humidity), our weathering chambers are able to increase the rate of material degradation by up to 8-times real life.

Samples of products are placed on a tray inside the Xenon Arc Chambers, where they are subjected to a ‘programme’ designed to mimic the conditions which the product is likely to face.

Different filters are used for different standards to expose your product to different spectra of UV light, while different sprays are used to replicate the environmental conditions expected for the product during its service lifetime.

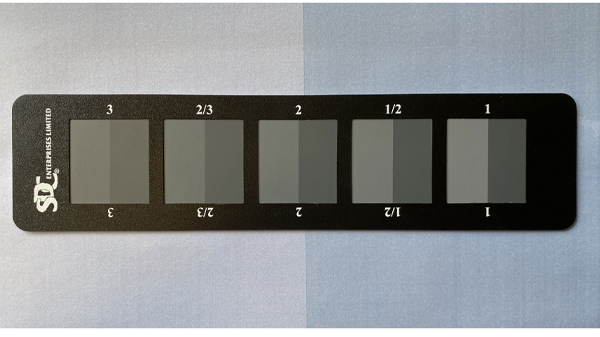

Specimens can be removed from the chamber at periodic intervals during the testing to determine their resilience to weathering, with tests including colour analysis, haze/transmission, tensile and de-lamination.

Inside an accelerated weathering chamber.

What happens if I don’t test?

In many industries, accelerated weathering reports from an independent laboratory is required in order to supply a product, especially in the automotive and textile industries.

However, even if a report is not required, weathering testing can be invaluable. Impact Solutions have helped companies overcome failures caused by unexpected weathering in products as diverse as pipe end caps, safety helmets and tanks. The picture opposite shows what happened to stadium seats which were not adequately tested.

What products need testing?

Anything that is likely to have sunlight exposure during its lifetime, whether inside or outside (interior or exterior weathering testing). Industries include automotive, textile, rubber, inks, paints, packaging, and plastics.