What are ISO & IEC flammability tests?

Like the UL94 tests, the IEC and the ISO has different types of fire tests to compare plastics material in terms of their burning behaviour. Each type of test requires a specific gas flow rate, flame height, specimen and flame orientation, and time of exposure to the flame. Likewise, measurements such as afterflame times, afterglow times and burning rate are performed. The results obtained are then compared against a standard set of test criteria and the material is given a rating based on the criteria it satisfies.

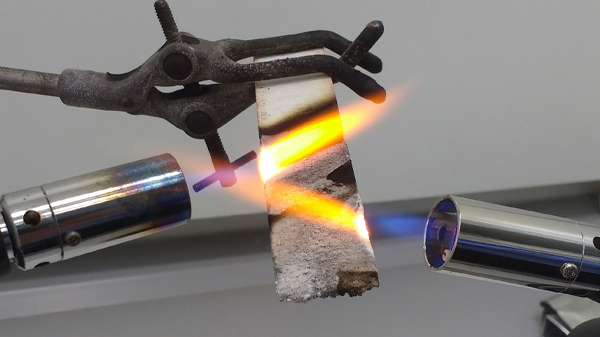

The figure, seen right, illustrates the flammability of material in relation to the ratings assigned, 5VA/VB being the least flammable while HB/HBF being the most flammable.

More Flammability Tests

| test/activity | rating | application |

| ISO EN 11925-2 | ||

| UN Test N.1 Division 4.1 | Non Combustible, PGII, PGIII | Test method for readily combustible solids to determine UN packaging group |

| BS EN 60695-11-10IEC 60695-11-10 method A | HB, HB40, HB75 | Polymeric materials used for parts in devices and appliances. Test method used as a means of comparing the rate of burning, extent/time of burning, material selection and quality control of polymeric materials. |

| BS EN 60695-11-10IEC 60695-11-10 method B | V-0, V-1 or V-2 | Polymeric materials used for parts in devices and appliances. Used for material selection and quality assurance. Cannot be used to classify materials used in building construction or finishing. |

| BS EN 60695-11-20IEC 60695-11-20 | 5VA or 5VB | Polymeric materials used for parts in devices and appliances. Used for material selection and quality assurance. Cannot be used to classify materials used in building construction or finishing. Can be used to classify non-metallic materials if found appropriate. |

| ISO 9773 | VTM-0,VTM-1 or VTM-2 | Plastic materials to be used as very thin films, generally not capable of supporting themselves in a horizontal position. These are usually assigned to substrates on flexible printed circuit boards. |

| ISO 9772 | HBF, HF-1 or HF-2 | Means of comparing the burning characteristics of foamed materials of like thickness density, cell size, skin irregularities and the effect of falling particles. It is useful for quality control, specification acceptance and research and development. |

| ISO 3795 | HB | Road vehicles, and tractors and machinery for agriculture and forestry – Determination of burning behaviour of interior materials. |